Concrete pipeline systems manufacturers continue to innovate as the industry strives for improved pipeline and manhole construction quality and performance, delivering reduced waste, lower costs, faster build times and minimised environmental impacts.

Production techniques continue to advance and the use of modern logistics systems ensure excellent product quality and reliable service.

Responsible sourcing of raw materials from local suppliers ensures that cradle to site “pipe miles” is low and high use of recycled materials keeps embodied impacts to a minimum.

The use of modern, integrally-cast high performance seals helps maintain water tightness and integrity of joints.

The design flexibility of concrete pipeline systems means that many special features can be incorporated in the factory and simply placed into position on site. These “offsite solutions” can replace lengthy in-situ operations, thus improving site safety and product quality, reducing waste, speeding-up installation and reducing costs.

An excellent example of an offsite solution introduced recently is a concrete manhole system, packed with many benefits that will satisfy designers, contractors and operators alike. The new manhole design offers:

Reduced construction time

Decreased installation costs

Improved safety on site

Superior quality

Watertight system

Reduced carbon footprint

Concrete Manhole Construction

Traditionally, manhole construction has required the base to be formed in-situ where building of the channel, connections and benching occurs in the trench, often in wet and unpleasant conditions. The process can take around 40 hours per manhole and is not always successful, particularly in terms of leakage where egress of waste water can lead to contaminated groundwater and ingress can contribute to the common problem of overloaded sewer networks plus increased energy usage and running costs at treatment works and pumping stations.

Concrete Manhole Design

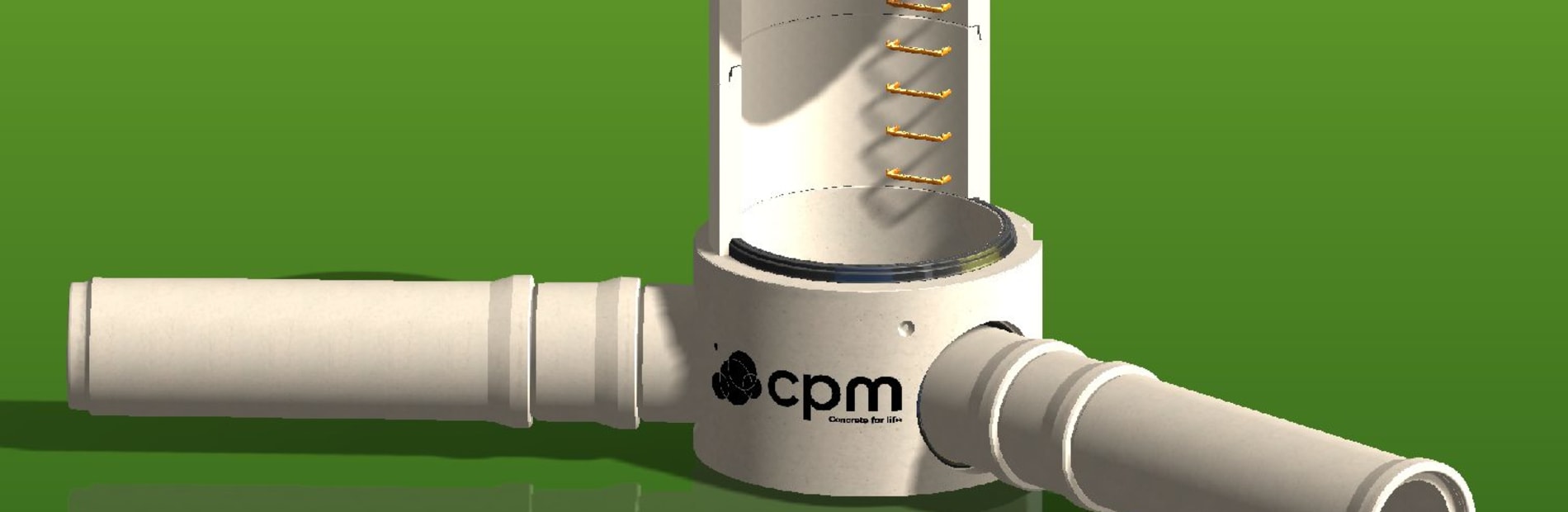

The new concrete manhole design comprises a precast concrete monolithic base unit, complete with channel and benching with predetermined combinations of inlet(s) and outlet and a new design of chamber ring with watertight, flexible joints and no lifting holes, thereby removing points of possible leakage.

Both base units and chamber rings are made with thicker, stronger walls. The robust design means that the requirement for a concrete surround is eliminated, unless specifically required. The excavation is backfilled sooner and there is less need for men to work in confined spaces. This reduces time spent in the excavation, further improving site safety and reducing installation costs.

Concrete Manhole Installation

Installation of the whole system is speedy and efficient. Once in position, wet trades are eliminated, formation of benching on site and sealing of lifting holes is avoided and follow-up operations can start immediately. Field trials indicate that time savings of over 30% can easily be achieved and costs reduced by well over 10%, particularly when installed without a concrete surround.

Enviromental Advantages

The system also yields environmental advantages as less concrete is used, there is less waste and less excavated material is disposed to landfill. An annual saving of over 22,000 tonnes of CO2e is estimated in the UK if all manholes manufactured by members of CPSA changed to the new precast base system.

The quality of material and finish is well above that normally achieved on site and the full system is manufactured under factory conditions by third party certified companies to ISO 9001 quality management system. Products are Kitemarked to BS EN 1917:2002 and BS 5911-3:2010Concrete Manholes and Inspection Chambers and tested under laboratory conditions.

UK Water companies have embraced the new precast manhole base system and given their acceptance to use the design for new projects in lieu of traditional in-situ construction and full acceptance is anticipated throughout the UK