Concrete Pipes

Marshalls Civils & Drainage offer an extensive range of precast concrete pipes with flexible spigot and socket joints from 300mm to 1800mm to BS EN 1916:2002 Class 120, ovoid pipes and perforated pipes for use in both foul and surface water applications.

Concrete sewer pipes dating back to Roman times have been discovered in the United Kingdom and users of Marshalls Civils & Drainage precast concrete pipes have the security of a design life of 120 years that ensures lifetime costs are kept to a minimum.

All precast concrete pipes manufactured to class 4 (DC4) sulphate resistance in accordance with the recommendations of BRE Special Digest.

Download the EPD for our reinforced pipes here.

Download the EPD for our unreinforced pipes here.

With an inherent strength and durability, concrete is an environmentally friendly and cost effective material that provides the following benefits:

- Increased cost savings

- Fast and easy installation

- Lower environmental impact

We have some useful video's for you to watch on installation, lifting and how to air test the pipe.

Division

Contact

01179 814500

Technical Downloads (18)

- declarations Download declarations

- civils and drainage water management brochure Download civils and drainage water management brochure

Certifications, Accreditations & Credentials

UKCA Declarations of Performance

- declarations Download declarations

Brochure Pages

- civils and drainage water management brochure Download civils and drainage water management brochure

Technical Documents

- guide to air-testing onsite Download guide to air-testing onsite

- Marshalls_Civils_and_Drainage_-_Pipe_Installation_Manual_-_April_2021_V4 Download Marshalls_Civils_and_Drainage_-_Pipe_Installation_Manual_-_April_2021_V4

- KM 06910 Mells Download KM 06910 Mells

- KM 06909 1 Pollington Download KM 06909 1 Pollington

- bpda guide for offloading deliveries Download bpda guide for offloading deliveries

- bpda technical brochure april 2021 Download bpda technical brochure april 2021

- bpda manual handling Download bpda manual handling

- pipe bedding Download pipe bedding

- BS EN ISO 45001:2018 Download BS EN ISO 45001:2018

- BS EN ISO 14001:2015 Download BS EN ISO 14001:2015

- BS EN ISO 9001:2015 Download BS EN ISO 9001:2015

- Achilles Building Confidence Download Achilles Building Confidence

- UKCA Mark PC01 Pollington Pipes V2 Download UKCA Mark PC01 Pollington Pipes V2

- CE Mark PC01 Pollington Pipes V2 Download CE Mark PC01 Pollington Pipes V2

- Concrete Pipe Storage Capacities Download Concrete Pipe Storage Capacities

- Concrete Pipe Installation Guide V4 Download Concrete Pipe Installation Guide V4

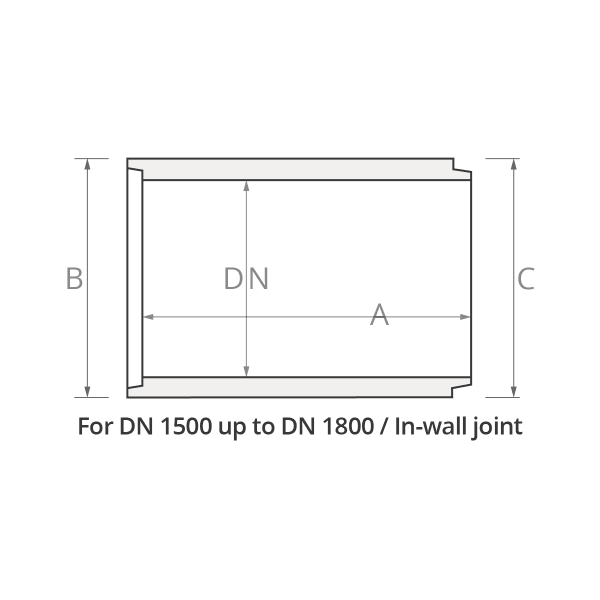

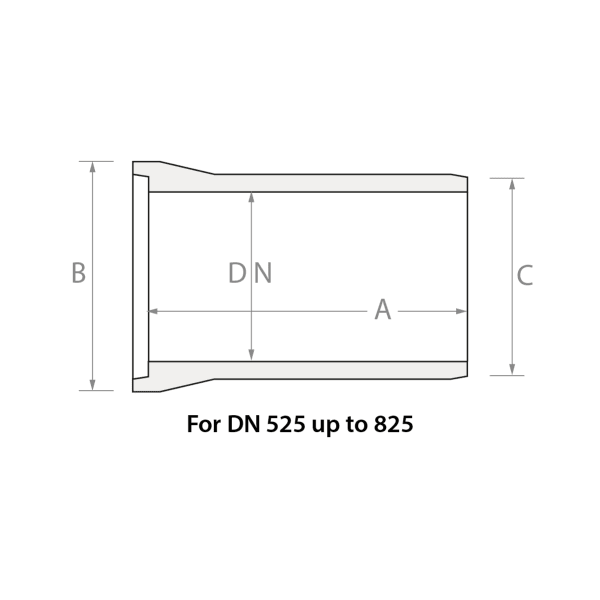

| Product Name | Core Diameter (mm) | Nominal Dimensions A (mm) | Nominal Dimensions B (mm) | Nominal Dimensions C (mm) | Angular Deflection (Degrees) | Joint Type | Approx Weight Of Pipe (kg) | Rocker Pipe Length (mm) | Butt Pipe Length (mm) |

|---|---|---|---|---|---|---|---|---|---|

| 1500mm Flexible Jointed Concrete Pipe | 1500 | 2500 | 1810 | 1810 | 0.48 | Lamell | 5230 | 1250 | 1250 |

| 1600mm Flexible Jointed Concrete Pipe | 1600 | 2500 | 1920 | 1920 | 0.44 | Lamell | 5702 | 1250 | 1250 |

| 1800mm Flexible Jointed Concrete Pipe | 1800 | 2500 | 2160 | 2160 | 0.4 | Lamell | 7150 | 1250 | 1250 |

Tabled dimensions are for guidance only. For accurate dimensions and weights please contact the Technical team, as these may vary.

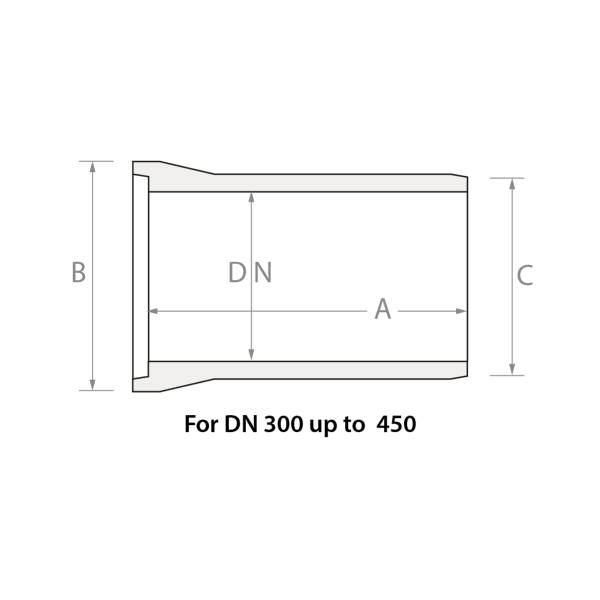

| Product Name | Core Diameter (mm) | Nominal Dimensions A (mm) | Nominal Dimensions B (mm) | Nominal Dimensions C (mm) | Angular Deflection (Degrees) | Joint Type | Approx Weight Of Pipe (kg) | Rocker Pipe Length (mm) | Butt Pipe Length (mm) |

|---|---|---|---|---|---|---|---|---|---|

| 0300mm Flexible Jointed Concrete Pipe | 300 | 1250 | 480 | 410 | 2.4 | Integral | 217 | 600 | 600 |

| 0300mm Flexible Jointed Concrete Pipe | 300 | 2500 | 497 | 410 | 2.4 | Integral | 420 | 600 | 600 |

| 0375mm Flexible Jointed Concrete Pipe | 375 | 2500 | 575 | 490 | 1.9 | Integral | 510 | 600 | 600 |

| 0450mm Flexible Jointed Concrete Pipe | 450 | 2500 | 675 | 575 | 1.6 | Integral | 705 | 600 | 600 |

Tabled dimensions are for guidance only. For accurate dimensions and weights please contact the Technical team, as these may vary.

| Product Name | Core Diameter (mm) | Nominal Dimensions A (mm) | Nominal Dimensions B (mm) | Nominal Dimensions C (mm) | Angular Deflection (Degrees) | Joint Type | Approx Weight Of Pipe (kg) | Rocker Pipe Length (mm) | Butt Pipe Length (mm) |

|---|---|---|---|---|---|---|---|---|---|

| 0525mm Flexible Jointed Concrete Pipe | 525 | 2500 | 760 | 670 | 1.4 | Integral | 900 | 600 | 600 |

| 0600mm Flexible Jointed Concrete Pipe | 600 | 2500 | 850 | 770 | 1.2 | Integral | 1200 | 600 | 600 |

| 0675mm Flexible Jointed Concrete Pipe | 675 | 2500 | 980 | 885 | 1.05 | Integral | 1680 | 1000 | 1250 |

| 0750mm Flexible Jointed Concrete Pipe | 750 | 2500 | 1060 | 980 | 0.95 | Integral | 1924 | 1000 | 1250 |

| 0825mm Flexible Jointed Concrete Pipe | 825 | 2500 | 1131 | 1005 | 0.9 | Integral | 1820 | 1250 | 1250 |

Tabled dimensions are for guidance only. For accurate dimensions and weights please contact the Technical team, as these may vary.

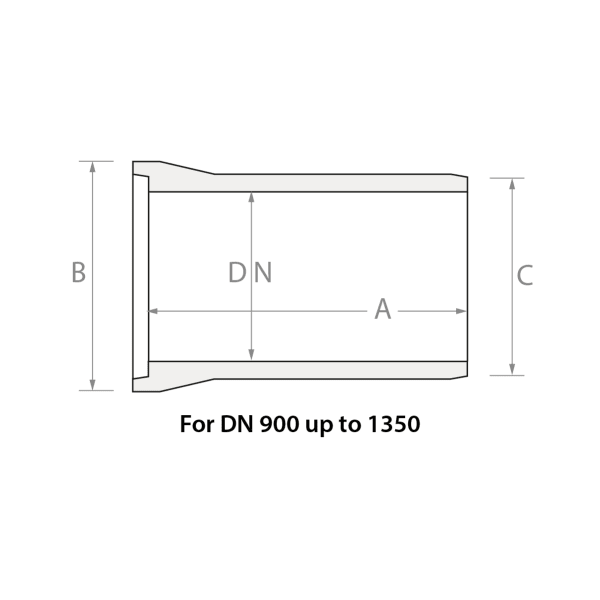

| Product Name | Core Diameter (mm) | Nominal Dimensions A (mm) | Nominal Dimensions B (mm) | Nominal Dimensions C (mm) | Angular Deflection (Degrees) | Joint Type | Approx Weight Of Pipe (kg) | Rocker Pipe Length (mm) | Butt Pipe Length (mm) |

|---|---|---|---|---|---|---|---|---|---|

| 0900mm Flexible Jointed Concrete Pipe | 900 | 2500 | 1235 | 1080 | 0.8 | Integral | 1920 | 1250 | 1250 |

| 1050mm Flexible Jointed Concrete Pipe | 1050 | 2500 | 1420 | 1260 | 0.7 | Integral | 2590 | 1250 | 1250 |

| 1200mm Flexible Jointed Concrete Pipe | 1200 | 2500 | 1590 | 1440 | 0.6 | Integral | 3550 | 1250 | 1250 |

| 1350mm Flexible Jointed Concrete Pipe | 1350 | 2500 | 1840 | 1620 | 0.53 | 'G' Ring | 4600 | 1250 | 1250 |

Tabled dimensions are for guidance only. For accurate dimensions and weights please contact the Technical team, as these may vary.

Concrete Pipes BIM Model

At Marshalls we work alongside appropriate guidelines in which we are able to provide high quality 3D objects of our products that contain rich data to satisfy that information required by our clients.

We strive to improve the relationship with stakeholders and the BIM process enables us to share the relevant information.

- Our BIM models are available to download directly from our BIM library.

- We have a range of models available in AutoDesk Revit format including CoBie, IFC and NBS data.